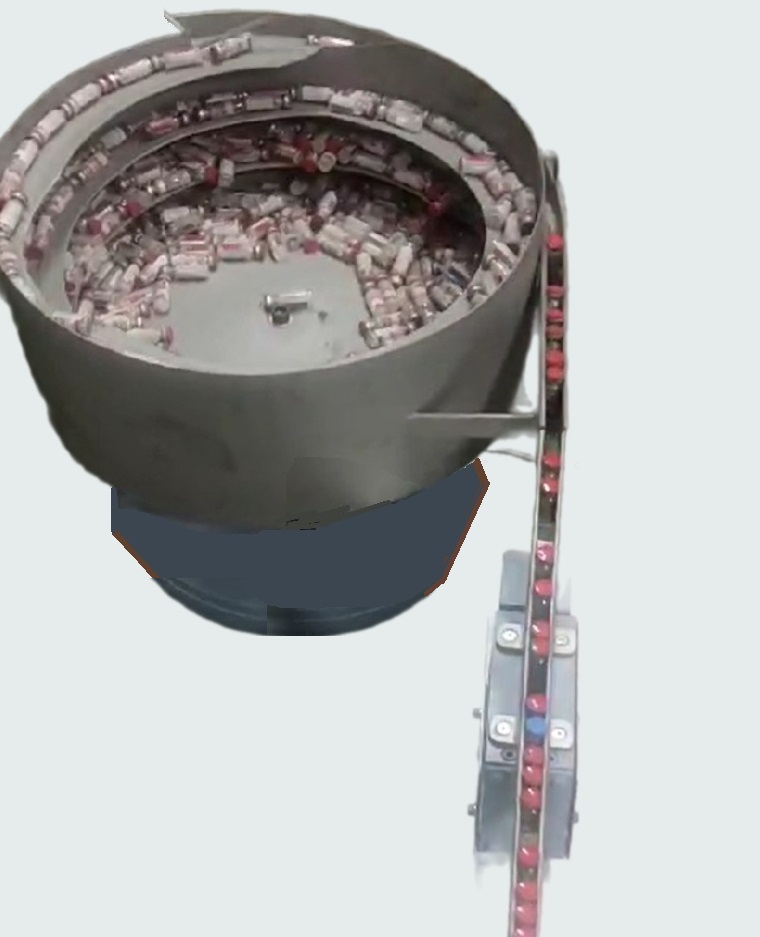

VIBRATORY BOWL FEEDERS

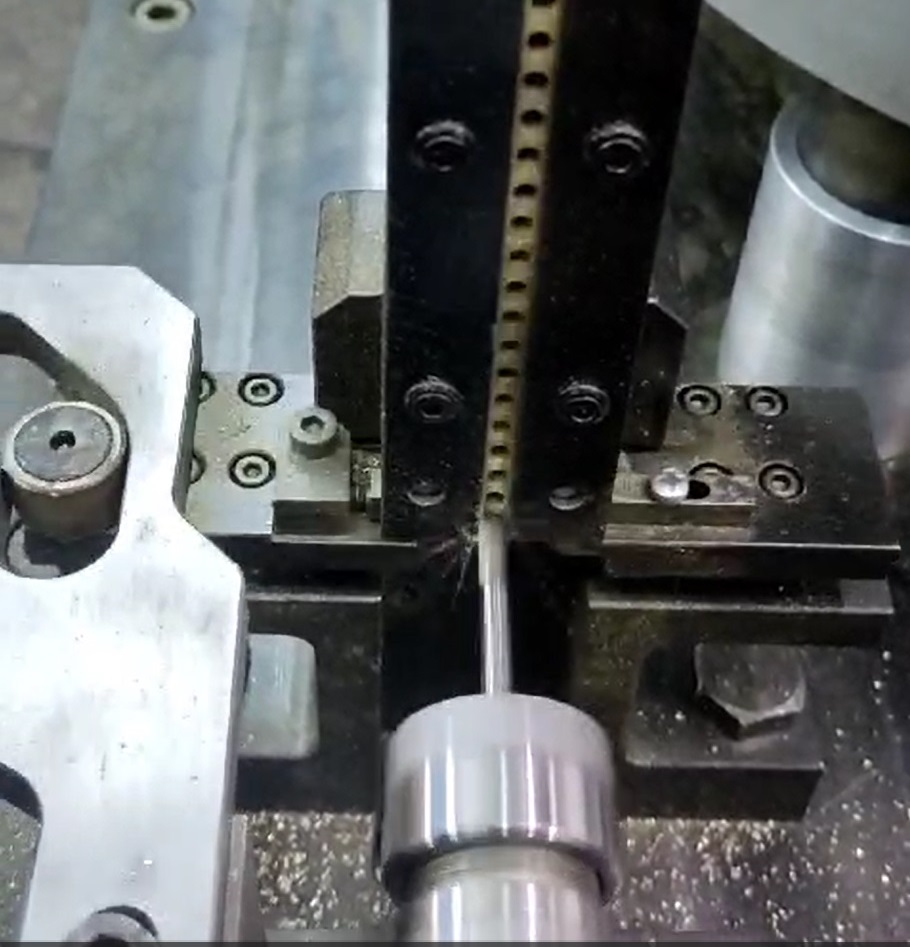

ÖZMAK OTOMASYON is specialized in the production of Vibratory Feeding Systems. Vibratory Bowl Feeder Machines are an innovative and effective automation solution widely preferred in factory automation. As shown, the workpieces are vibrated at the appropriate frequency within a vibratory bowl allowing for their transfer via a trough-passing system. During this process, mechanical interventions known as "traps" are helping the parts to convert into an appropriate position. Implementing these traps in the correct sequence and timing requires significant engineering and R&D efforts. The successful operation of the process depends on both the material composition and the product shape. As shown, the workpiece is brought step-by-step and safely to the desired orientation. If there is an additional work process that needs to be incorporated, we can integrate it into the system. For example, numerous mechanical processes such as drilling, gluing, countersinking, and tapping can be automated. Our company uses the highest quality sheet metal and technical materials in its products. The servo and electrical motors we utilize are selected from top-quality and technological products. Additionally, control panels and software support can be added if desired. In this regard, our company has established numerous lines in our customers factories. All our machines undergo extensive testing before shipment. After completing these tests, our machines are dispatched, and installation support is provided upon request. The flooring where our machines are installed should also be well considered. Therefore, we offer information and consulting services regarding area selection and floor preparation. Process speed is naturally one of the most prominent issues. Depending on the material composition and shape, the process speed may show variations. As company, we perform top-level engineering work to meet our customer's expectations. Our preliminary studies can take several weeks. For this reason, we need to obtain a sufficient number of samples that are suitable for real conditions for each project concerning workpieces. Thanks to our extensive experience, we achieve successful results in terms of competitiveness, speed, and efficiency in the production of vibratory bowl feeders.

A successful work process relies on establishing the right steps and workflow. So far, we have completed numerous projects of vibratory bowl feeders in both nationwide and in international markets. We have thoroughly analyzed the behaviors of many different types of materials. In this regard, we have a deep understanding of how to transfer workpieces made from various materials, including steel, brass, copper, all types of plastics, rubber, stainless steel, and aluminum. The machines we produce require special craftsmanship and manual labor. The types and numbers of traps that need to be set up along the troughs vary for each workpiece. Being able to produce such a machine is the result of years of accumulated experience. It is our greatest motivation to see that our customers can operate at maximum efficiency with the help of our expertise and technical capabilities.

PROCESS IMAGES: